Wrapping up a semester in the clay lab is much like any other college course. There is a rush to get projects and papers completed and preparation to do for final exams. Clay, however, tends to have a mind of its own and doesn’t lend itself well to last minute crunches to dry, bisque fire, glaze, and glaze fire. For relatively simple shapes and pieces that do not include a lot of assembled pieces, a faster drying cycle isn’t a huge risk. Generally, a very slow ramp up of the bisque firing takes care of any moisture that would otherwise be disastrous in a faster firing cycle. Complicated pieces like the one shown here include many slip-slurried connections and numerous variations in clay thickness. Out of an abundance of caution, I often wrap complex pieces up and allow them to dry slowly over several week’s time. This one was finished just a few days ago and is headed for the kiln in less than a week…needless to say, I am a bit anxious. Should disaster strike and the kiln gods frown upon my rush, at least I will have a few images for the memorial. *sigh*

Wrapping up a semester in the clay lab is much like any other college course. There is a rush to get projects and papers completed and preparation to do for final exams. Clay, however, tends to have a mind of its own and doesn’t lend itself well to last minute crunches to dry, bisque fire, glaze, and glaze fire. For relatively simple shapes and pieces that do not include a lot of assembled pieces, a faster drying cycle isn’t a huge risk. Generally, a very slow ramp up of the bisque firing takes care of any moisture that would otherwise be disastrous in a faster firing cycle. Complicated pieces like the one shown here include many slip-slurried connections and numerous variations in clay thickness. Out of an abundance of caution, I often wrap complex pieces up and allow them to dry slowly over several week’s time. This one was finished just a few days ago and is headed for the kiln in less than a week…needless to say, I am a bit anxious. Should disaster strike and the kiln gods frown upon my rush, at least I will have a few images for the memorial. *sigh*

Archive for November, 2010

Quick Bisque Anxiety

11.25

New Ocarinas and a MugPhlute

11.21

The last batch of glaze tests included a few pinch pot ocarinas and a MugPhlute. The natural look of the reduction fired stoneware with minimal glaze accents seems to work well. The pieces in this image are all high-fired stoneware with red iron oxide brushed into the textured and stamped features. The glaze is St. John’s Black, applied with a brush. The Bailey gas kiln, loaded with these clay instruments as well as student projects from this semester, was fired to cone 10.

The last batch of glaze tests included a few pinch pot ocarinas and a MugPhlute. The natural look of the reduction fired stoneware with minimal glaze accents seems to work well. The pieces in this image are all high-fired stoneware with red iron oxide brushed into the textured and stamped features. The glaze is St. John’s Black, applied with a brush. The Bailey gas kiln, loaded with these clay instruments as well as student projects from this semester, was fired to cone 10.

This semester’s wheel-throwing course pulled me away from making the usual quantity of ceramic musical instruments, but it has also opened new avenues to explore. Having a respectable palette of stamping, texturing, and glazing combinations will make future project planning easier and, hopefully, more predictable.

Kiln Opening

11.18

I have read numerous articles in the ceramic magazines floating around about celebrations and sales associated with the opening of a freshly fired (and cooled-down) kiln. Personally, I know the excitement and anticipation as a kiln cart is slowly and carefully pulled free, and shelves full of shiny pots suddenly appear to emerge from their firebrick womb. That experience is amazing. It is rarely what the artist envisioned completely, but there are generally surprises that elevate the spirit even when everything isn’t just perfect.

I have read numerous articles in the ceramic magazines floating around about celebrations and sales associated with the opening of a freshly fired (and cooled-down) kiln. Personally, I know the excitement and anticipation as a kiln cart is slowly and carefully pulled free, and shelves full of shiny pots suddenly appear to emerge from their firebrick womb. That experience is amazing. It is rarely what the artist envisioned completely, but there are generally surprises that elevate the spirit even when everything isn’t just perfect.

This past week’s firing was a success. There are a number of keepers and a bunch of glaze testing tiles that show promise for the next round. The kiln opening was rather bland, however…just a couple of people tugging at a heavy cart without fanfare, but at least with a few instruments for future fanfares.

Clay Students Raising Money

11.04

I think it is a pretty cool idea when clay artists band together to raise funds in a learning community context. Matt Chenoweth posted a story recently about the 1st Annual Ceramics Guild ChiliFest where several Indiana State University clay artists contributed bowls and a cooperating restaurant furnished the chili. Customers pay a little more than they are accustomed for chili but walk away smiling because they also hold a unique, hand crafted bowl that probably would have cost them more if they had discovered it at a craft fair. The student organization walks away with much needed funds for their project, and the restaurant is generally thrilled to have offered their customers something beyond the day-to-day menu without a large capital outlay. Happy customers, happy restaurant, happy students…as I said at the beginning, pretty cool idea! The old learning community guy in me would tell you that the common focus of the student group to raise project money by exercising a reflective, skill process (from mud to a finished, sold product) is a pattern that will be life-long, valuable memory.

I’m not completely certain where the bowl-a-thon fund raising concept originated, but credit to Empty Bowls is a must mention. Salute to all!

From Mud to Music

11.04

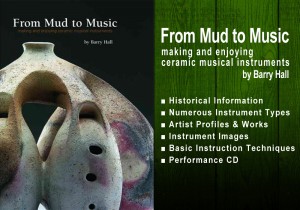

Barry Hall’s book, From Mud to Music, was given to me as a birthday present just about three years ago. After three years, I still refer to the book for information and inspiration. Last year I reviewed the book for Amazon.com and stand by my recommendation and commentary. I am also thinking that there is something more that is worthy of exploration…

Barry Hall’s book, From Mud to Music, was given to me as a birthday present just about three years ago. After three years, I still refer to the book for information and inspiration. Last year I reviewed the book for Amazon.com and stand by my recommendation and commentary. I am also thinking that there is something more that is worthy of exploration…

I would like to believe that there are many others who can describe their personal musical journeys as something that began in elementary school and progressed in some manner as an instrumentalist in high school or college and/or beyond. Living in a home with a musical genius father, I was fortunate to be exposed to all sorts of instruments and the constant repairs and constructions that go into keeping a band/orchestra functioning. I have my doubts that many students appreciate the history of their instruments, much less the skills involved in transforming raw materials into something that allows musicians to play together collectively/harmoniously.

Enter the book, from Mud to Music. Even if it is on a primitive scale, exposing a student to the complete process of taking a lump of clay and transforming it into a playable instrument is something that I believe would be fascinating and self-gratifying. After reading of historical instrument constructions that are thousands of years old, I found it humbling to think that less technical/advanced/pre-industrial revolution artists worked with very similar raw materials to those available today and successfully constructed playable devices…artistic works that actually play, beautifully. Amazing. I have asked myself several times, “What would a semester-long course look like that engages students in a cross-curricula study of ancient ceramic instrument history, clay instrument construction, musical composition, and perhaps musical performance?” With complete respect for Mr. Hall’s book, the working title for my concept/course is From Clay to Concert…part historical research, part clay construction/experimentation, part musical composition, and part performance. I may just be spit valve full, but with the right students this could be an awesome class. If this is ever going to materialize, it is time for Mud to Music inspiration to move from paper to proposal.

Wheel-Thrown Bottles

11.03

Given the choice between making vases or making bottles, I chose the latter. The decision probably has something to do with a home that is full of great examples created by the real ceramic artist of the family…and something to do with the cool factor of making tall bottles with unusual stoppers. I have no idea what I will do with any survivors from the bisque and gas firings, but I suspect that empty Etsy account may finally have entries just in time for Christmas.

Given the choice between making vases or making bottles, I chose the latter. The decision probably has something to do with a home that is full of great examples created by the real ceramic artist of the family…and something to do with the cool factor of making tall bottles with unusual stoppers. I have no idea what I will do with any survivors from the bisque and gas firings, but I suspect that empty Etsy account may finally have entries just in time for Christmas.

The Pricing Dilemma

Each bottle takes about an hour to throw and join…excluding some drying time between throwing and joining the sections. Add another hour for trimming, decorating, and clean-up and I have a greenware piece ready that must dry slowly. Stoppers generally take another hour to throw, carve, clean-up, and fit. By the time bisque firing and glaze firing are complete, each tall bottle has nearly 5 hours of my time committed to the project in a process that takes about two weeks from start to finish. A quick Google of handmade ceramic bottles returns pricing results that range from $55 to $200, so, somewhere in the $60 to $75 range seems to be a reasonable target. Your thoughts are appreciated.

The Details

Any bottle that I make that is over 12″ tall is thrown on the wheel in two pieces (usually about 8″-10″ each), then joined and completed while still attached to the wheel head. Stoneware clay is my preference, but porcelain makes highly polished bottles possible although they are a bit more challenging to produce. I have not ventured into the world of really tall bottles, made of three joined pieces, but the possibilities for horn shaped pieces constructed using that technique are certainly a possibility (with kiln height limits taken into consideration). I am including the MugPhlute stamp on all of these pieces since they do include a unique stopper with an instrumental musical theme.

Glaze images coming soon (I hope).